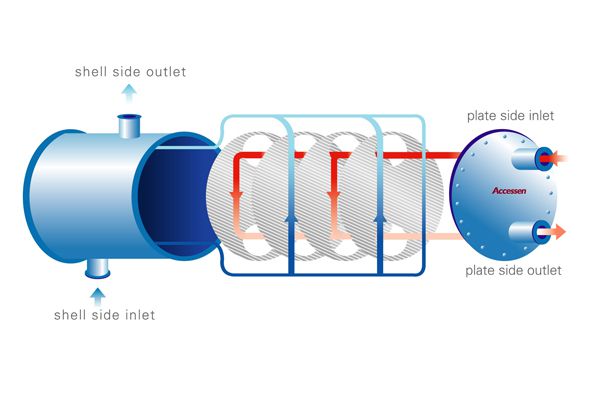

All-Welded Plate & Shell Heat Exchanger

Retains the full counter-current heat exchange characteristics of the detachable plate heat exchanger, which is 3-5 times more efficient than the traditional shell-and-tube heat exchanger. There are no gaskets on the original semi-welded heat exchanger. Depending on the application, the plate and frame can be differentiated into three types:

1. Which cannot be disassembled

2. Detachable on one side

3. Detachable on both sides.

| Plate Material | Media |

| Stainless steel Alloy 316L/Alloy 304 | Pure water, Revir Water, Edible oil, Mineral Oil. |

| Titanium | Sea Water, Salt Water, Salt Material. |

| Ni | High concentration caustic soda. |

| Allay C276 | Concentrated Sulfuric Acid, Hydrochloric Acid, Phosphoric Acid. |

Applications:

- Machinery manufacture.

- Marine.

- Desalination.

- Electrical Energy.

- Pharmaceuticals.

- Food & Beverage

- Pharmaceuticals.

- Paper Industry.

- Refrigeration

- Industrial, Organic Chemical.

Benefits:

- Flowpath design of the plate for the perfect distribution, no dead zone.

- Ultra-wide flow.

- Non-contract guarantee.

- The largest single-sided channel up to 5-20 mm.

Specifications:

- Maximum processing capacity: 2500m³/h.

- Maximum design pressure: 60bar.

- Maximum temperature: 500℃

- Plate materials: AISI304, 316, 316L, Titanium, Hastelloy, Ni, SMO254

Which certificates are available for the heat exchangers?

ASME, ISO, AHRI, BV, DNV etc… Case by case certificate was allowed.